Dental Electric Oil-Free Air Compressor WJ750-10A25/A

Product performance: (Note: can be customized according to user requirements)

|

Model name |

Flow performance |

work pressure |

input power |

speed |

volume |

Net weight |

Overall dimension |

|||||

|

0 |

2 |

4 |

6 |

8 |

(BAR) |

(WATTS) |

(RPM) |

(L) |

(Gal) |

(KG) |

L×W×H(CM) |

|

|

WJ750-10A25/A (one air compressor for one air compressor) |

135 |

97 |

77 |

68 |

53 |

7.0 |

750 |

1380 |

50 |

13.2 |

42 |

41×41×75 |

Scope of application

Provide oil-free compressed air source, applicable to dental equipment and other similar equipment and tools.

Product material

The tank body formed by steel die, sprayed with silver white paint, and the main motor is made of steel wire.

Overview of working principle

Working principle of compressor: oil-free air compressor is a miniature reciprocating piston compressor. The motor driven by a single shaft and has a symmetrical distribution of crank and rocker mechanical structure. The main motion pair is piston ring, and the secondary motion pair is aluminum alloy cylindrical surface. The motion pair self-lubricated by the piston ring without adding any lubricant. The reciprocating movement of the crank and rocker of the compressor makes the volume of the cylindrical cylinder change periodically, and the volume of the cylinder changes twice in opposite directions after the motor runs for one week. When the positive direction is the expansion direction of the cylinder volume, the cylinder volume is vacuum. The atmospheric pressure is greater than the air pressure in the cylinder, and the air enters the cylinder through the inlet valve, which is the suction process; when the opposite direction is the direction of volume reduction, the gas entering the cylinder is compressed, and the pressure in the volume increases rapidly. When the pressure is greater than the atmospheric pressure, the exhaust valve opened, and this is the exhaust process. The structural arrangement of single shaft and double cylinders makes the gas flow of the compressor twice that of the single cylinder when the rated speed is fixed, and makes the vibration and noise generated by the single cylinder compressor well solved, and the overall structure is more compact.

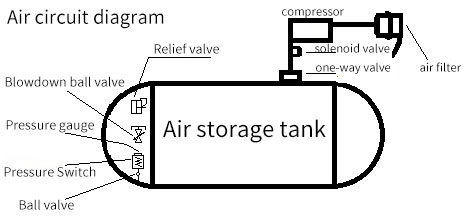

Working principle of the whole machine (attached figure)

Air enters the compressor from the air filter, and the rotation of the motor makes the piston move back and forth to compress the air. So that the pressure gas enters the air storage tank from the air outlet through the high-pressure metal hose by opening the one-way valve, and the pointer display of the pressure gauge will rise to 7Bar, and then the pressure switch will automatically close, and the motor will stop working. At the same time, the air pressure in the compressor head will reduced to zero Bar through the solenoid valve. At this time, the air switch pressure and the air pressure in the air tank drop to 5Bar, the pressure switch automatically starts, and the compressor starts to work again.

Product Overview

Because of its low noise and high air quality, dental electric oil-free air compressor is widely used in electronic dust blowing, scientific research, medical and health care, food safety, and community carpentry decoration and other workplaces;

The dental electric oil-free air compressor provides a quiet and reliable compressed air source for laboratories, dental clinics, hospitals, research institutes and other places. The noise is as low as 40 decibels. It can be placed anywhere in the work area without causing noise pollution. It is very suitable for being an independent gas supply center or OEM application range.

Characteristics of dental electric oil-free air compressor

1. Compact structure, small size and light weight;

2. The exhaust is continuous and uniform, without the need for inter-stage intermediate tank and other devices;

3. Small vibration, less vulnerable parts, no need for large and heavy foundation;

4. Except for bearings, the internal parts of the machine do not need lubrication, save oil, and do not pollute the compressed gas;

5. High speed;

6. Small maintenance and convenient adjustment;

7. Quiet, green, environmental friendly, no noise pollution, no need to add lubricating oil;

8. Powerful, super energy-saving and stable operation.

Machine noise≤60DB

|

Machine Noise≤60DB |

|||

|

Volume analogy |

|||

|

300dB 240 dB 180 dB 150 dB 140 dB 130 dB 120 dB 110 dB 100 dB 90 dB |

Pliny type volcanic eruption Secondary to Plinian volcanic eruption Ordinary volcanic eruption Rocket launch Jets take off Propeller aircraft takeoff Ball mill operation Electric saw work Tractor start A noisy road |

80 dB 70 dB 60 dB 50 dB 40 dB 30 dB 20 dB 10 dB 0 dB |

General vehicle driving Speak loudly General speaking Office Library, reading room Bedroom Whisper softly The wind blowing leaves rustling Just caused hearing |

Speak loudly—The noise of the machine is about 60 dB, and the higher the power, the higher the noise will be.

From the date of production, the product has a safe use period of 5 years and a warranty period of 1 year.

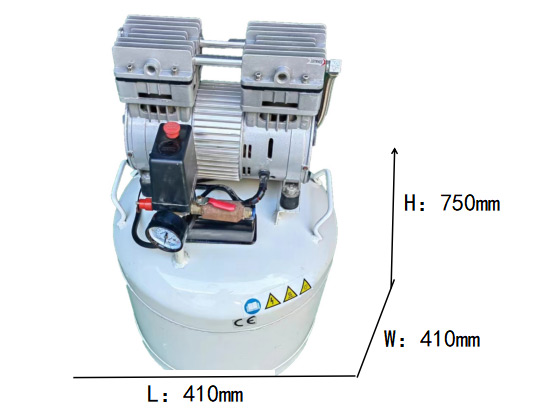

Product appearance dimension drawing: (length:410mm×Width:410mm×Height:750mm)

Performance illustration

The main function of the dental air compressor is to provide power for the control of dental equipment and treatment machines such as water/air spray guns, turbine handpieces, and sandblasting machines to ensure continuous and reliable surgical operations.

When choosing an air compressor, stability is the most important factor. A good dental compressor works reliably behind the scenes, freeing healthcare professionals to focus on treatment.

Dental compressed air must be clean and hygienic, so the air humidity must be minimized and completely free from oily or solid particle contamination, as these impurities will threaten the service life of high-quality dental materials, as well as the functioning of precision instruments, prescribed for patients Hygiene and sterility conditions must also be met.

The dryer equipped on the air compressor can not only ensure a stable dryness, but also ensure continuous operation without a regeneration time. The air polluted by moisture, oil and small particles is not suitable for dental treatment. The lower pressure dew point of the air compressor ensures high-quality, odorless and tasteless compressed air.

One of the problems with compressed air is its high water content, which makes it an ideal breeding ground for bacteria. Dental air compressors have a built-in dryer that removes as much moisture as possible and delivers dry air to the patient. This works in conjunction with a filter to clean the air and trap any microbes present so they don’t transfer to the patient’s mouth. Health and safety regulations may require dryers and filters to protect patients and regular cleaning to keep patients clean and organized.

Another problem could be oil in the air. Compressors require lubrication to function, but oil can get into the airstream, potentially threatening the health of the patient and compromising the surgical procedure. Some devices are oil-free, while others have special sealing systems to prevent leaks. Dental air compressors can also be designed to run quietly, which can reduce stress for patients who are bothered by the sound of large engines that may be running near the operating room.