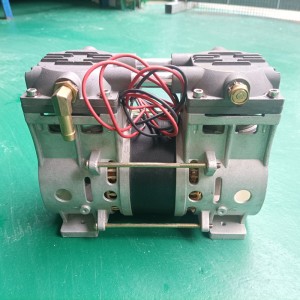

Main Engine Of Oil-Free Air Compressor ZW380-72/2AF

Size

Length: 251mm × Width: 128mm × Height: 185mm

Product performance: (other models and performances can be customized according to user's requirements)

|

Power Supply |

Model Name |

Flow Performance |

Maximum Pressure |

Ambient Temperature |

Input Power |

Speed |

Net Weight |

|||||

|

0 |

2.0 |

4.0 |

6.0 |

8.0 |

(BAR) |

MIN (℃) |

MAX (℃) |

(WATTS) |

(RPM) |

(KG) |

||

|

AC 220V 50Hz |

ZW380-72/2AF |

102 |

72 |

- |

- |

- |

2.5 |

0 |

40 |

400W |

1400 |

5 |

Scope of application

Provide oil-free compressed air source and auxiliary tools applicable to relevant products.

Product features

1. Piston and cylinder without oil or lubricating oil;

2. Permanently lubricated bearings;

3. Stainless steel valve plate;

4. Lightweight die-cast aluminum components;

5. Long-life, high-performance piston ring;

6. Hard-coated thin-walled aluminum cylinder with large heat transfer;

7. Dual fan cooling, good air circulation of motor;

8. Double inlet and exhaust pipe system, convenient for pipe connection;

9. Stable operation and low vibration;

10. All aluminum parts that are easy to corrode in contact with compressed gas shall be protected;

11. Patented structure, low noise;

12. CE/ROHS/ETL certification;

13. It can be applied to many fields.

Standard products

We have a wide range of knowledge and combine them with application fields to provide customers with innovative and cost-effective solutions, so that we maintain a long-term and lasting cooperative relationship with customers.

Our engineers have been developing new products for a long time to meet the requirements of the changing market and new application fields. They have also continued to improve the products and the production process of the products, which has greatly improved the service life of the products, reduced the maintenance costs, and reached an unprecedented level of product performance.

Flow - maximum free flow 1120L/min.

Pressure - maximum working pressure 9 bar.

Vacuum - maximum vacuum - 980mbar.

Product material

The motor is made of pure copper and the shell is made of aluminum.

Product explosion diagram

|

22 |

WY-501W-J24-06 |

crank |

2 |

Gray Iron HT20-4 |

|||

|

21 |

WY-501W-J024-10 |

right fan |

1 |

Reinforced Nylon 1010 |

|||

|

20 |

WY-501W-J24-20 |

Metal gasket |

2 |

Stainless steel heat-resistant and acid-resistant steel plate |

|||

|

19 |

WY-501W-024-18 |

intake valve |

2 |

Sandvik7Cr27Mo2-0.08-T2 |

|||

|

18 |

WY-501W-024-17 |

valve plate |

2 |

Die-cast aluminum alloy YL102 |

|||

|

17 |

WY-501W-024-19 |

Outlet valve gas |

2 |

Sandvik7Cr27Mg2-0.08-T2 |

|||

|

16 |

WY-501W-J024-26 |

limit block |

2 |

Die-cast aluminum alloy YL102 |

|||

|

15 |

GB/T845-85 |

Cross recessed pan head screws |

4 |

lCr13Ni9 |

M4*6 |

||

|

14 |

WY-501W-024-13 |

Connecting pipe |

2 |

Aluminum and aluminum alloy extruded rod LY12 |

|||

|

13 |

WY-501W-J24-16 |

Connecting pipe sealing ring |

4 |

Silicone rubber compound 6144 for the defense industry |

|||

|

12 |

GB/T845-85 |

Hex socket head cap screw |

12 |

M5*25 |

|||

|

11 |

WY-501W-024-07 |

cylinder head |

2 |

Die-cast aluminum alloy YL102 |

|||

|

10 |

WY-501W-024-15 |

cylinder head gasket |

2 |

Silicone rubber compound 6144 for the defense industry |

|||

|

9 |

WY-501W-024-14 |

Cylinder sealing ring |

2 |

Silicone rubber compound 6144 for the defense industry |

|||

|

8 |

WY-501W-024-12 |

the cylinder |

2 |

Aluminum and aluminum alloy thin-walled tube 6A02T4 |

|||

|

7 |

GB/T845-85 |

Cross Recessed Countersunk Screws |

2 |

M6*16 |

|||

|

6 |

WY-501W-024-11 |

Connecting rod pressure plate |

2 |

Die-cast aluminum alloy YL104 |

|||

|

5 |

WY-501W-024-08 |

Piston Cup |

2 |

Polyphenylene filled PTFE V plastic |

|||

|

4 |

WY-501W-024-05 |

connecting rod |

2 |

Die-cast aluminum alloy YL104 |

|||

|

3 |

WY-501W-024-04-01 |

left box |

1 |

Die-cast aluminum alloy YL104 |

|||

|

2 |

WY-501W-024-09 |

left fan |

1 |

Reinforced Nylon 1010 |

|||

|

1 |

WY-501W-024-25 |

wind cover |

2 |

Reinforced Nylon 1010 |

|||

|

Serial number |

Drawing number |

Names and specifications |

Quantity |

Material |

Single piece |

Total parts |

Note |

|

Weight |

|||||||

|

34 |

GB/T276-1994 |

Bearing 6301-2Z |

2 |

||||

|

33 |

WY-501W-024-4-04 |

rotor |

1 |

||||

|

32 |

GT/T9125.1-2020 |

Hex Flange Lock Nuts |

2 |

||||

|

31 |

WY-501W-024-04-02 |

stator |

1 |

||||

|

30 |

GB/T857-87 |

light spring washer |

4 |

5 |

|||

|

29 |

GB/T845-85 |

Cross recessed pan head screws |

2 |

Carbon structural steel ML40 for cold upset forging |

M5*120 |

||

|

28 |

GB/T70.1-2000 |

hex head bolt |

2 |

Carbon structural steel ML40 for cold upset forging |

M5*152 |

||

|

27 |

WY-501W-024-4-03 |

lead protective circle |

1 |

||||

|

26 |

WY-501W-J024-04-05 |

Right box |

1 |

Die-cast aluminum alloy YL104 |

|||

|

25 |

GB/T845-85 |

Hex socket head cap screw |

2 |

M5*20 |

|||

|

24 |

GB/T845-85 |

Hexagon Socket Flat Point Set Screws |

2 |

M8*8 |

|||

|

23 |

GB/T276-1994 |

Bearing 6005-2Z |

2 |

||||

|

Serial number |

Drawing number |

Names and specifications |

Quantity |

Material |

Single piece |

Total parts |

Note |

|

Weight |

|||||||