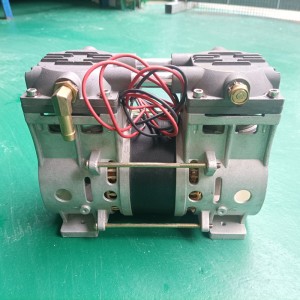

Main Engine Of Oil-Free Air Compressor ZW750-75/7AF

size

Length:271mm×Width:128mm×Height:214m

Product performance: (other models and performances can be customized according to user's requirements)

|

Power Supply |

Model Name |

Flow Performance |

Maximum Pressure |

Ambient Temperature |

Input Power |

Speed |

Net Weight |

|||||

|

0 |

2.0 |

4.0 |

6.0 |

8.0 |

(BAR) |

MIN (℃) |

MAX (℃) |

(WATTS) |

(RPM) |

(KG) |

||

|

AC 220V 50Hz |

ZW750-75/7AF |

135 |

96.7 |

76.7 |

68.3 |

53.3 |

8.0 |

0 |

40 |

780W |

1380 |

10 |

Product scope of application

Provide oil-free compressed air source and auxiliary tools applicable to relevant products.

Product features

1. Piston and cylinder without oil or lubricating oil;

2. Permanently lubricated bearings;

3. Stainless steel valve plate;

4. Lightweight die-cast aluminum components;

5. Long-life, high-performance piston ring;

6. Hard-coated thin-walled aluminum cylinder with large heat transfer;

7. Dual fan cooling, good air circulation of motor;

8. Double inlet and exhaust pipe system, convenient for pipe connection;

9. Stable operation and low vibration;

10. All aluminum parts that are easy to corrode in contact with compressed gas shall be protected;

11. Patented structure, low noise;

12. CE/ROHS/ETL certification;

13. Scientific and compact design, more gas production per unit power.

Standard products

We have a wide range of knowledge and combine them with application fields to provide customers with innovative and cost-effective solutions, so that we maintain a long-term and lasting cooperative relationship with customers.

Our engineers have been developing new products for a long time to meet the requirements of the changing market and new application fields. They have also continued to improve the products and the production process of the products, which has greatly improved the service life of the products, reduced the maintenance costs, and reached an unprecedented level of product performance.

Flow - maximum free flow 1120L/min.

Pressure - maximum working pressure 9 bar.

Vacuum - maximum vacuum - 980mbar.

Product material

The motor is made of pure copper and the shell is made of aluminum.

Product explosion diagram

|

22 |

WY-501W-J24-06 |

crank |

2 |

Gray Iron HT20-4 |

|||

|

21 |

WY-501W-J024-10 |

right fan |

1 |

Reinforced Nylon 1010 |

|||

|

20 |

WY-501W-J24-20 |

Metal gasket |

2 |

Stainless steel heat-resistant and acid-resistant steel plate |

|||

|

19 |

WY-501W-024-18 |

intake valve |

2 |

Sandvik7Cr27Mo2-0.08-T2 |

|||

|

18 |

WY-501W-024-17 |

valve plate |

2 |

Die-cast aluminum alloy YL102 |

|||

|

17 |

WY-501W-024-19 |

Outlet valve gas |

2 |

Sandvik7Cr27Mg2-0.08-T2 |

|||

|

16 |

WY-501W-J024-26 |

limit block |

2 |

Die-cast aluminum alloy YL102 |

|||

|

15 |

GB/T845-85 |

Cross recessed pan head screws |

4 |

lCr13Ni9 |

M4*6 |

||

|

14 |

WY-501W-024-13 |

Connecting pipe |

2 |

Aluminum and aluminum alloy extruded rod LY12 |

|||

|

13 |

WY-501W-J24-16 |

Connecting pipe sealing ring |

4 |

Silicone rubber compound 6144 for the defense industry |

|||

|

12 |

GB/T845-85 |

Hex socket head cap screw |

12 |

M5*25 |

|||

|

11 |

WY-501W-024-07 |

cylinder head |

2 |

Die-cast aluminum alloy YL102 |

|||

|

10 |

WY-501W-024-15 |

cylinder head gasket |

2 |

Silicone rubber compound 6144 for the defense industry |

|||

|

9 |

WY-501W-024-14 |

Cylinder sealing ring |

2 |

Silicone rubber compound 6144 for the defense industry |

|||

|

8 |

WY-501W-024-12 |

the cylinder |

2 |

Aluminum and aluminum alloy thin-walled tube 6A02T4 |

|||

|

7 |

GB/T845-85 |

Cross Recessed Countersunk Screws |

2 |

M6*16 |

|||

|

6 |

WY-501W-024-11 |

Connecting rod pressure plate |

2 |

Die-cast aluminum alloy YL104 |

|||

|

5 |

WY-501W-024-08 |

Piston Cup |

2 |

Polyphenylene filled PTFE V plastic |

|||

|

4 |

WY-501W-024-05 |

connecting rod |

2 |

Die-cast aluminum alloy YL104 |

|||

|

3 |

WY-501W-024-04-01 |

left box |

1 |

Die-cast aluminum alloy YL104 |

|||

|

2 |

WY-501W-024-09 |

left fan |

1 |

Reinforced Nylon 1010 |

|||

|

1 |

WY-501W-024-25 |

wind cover |

2 |

Reinforced Nylon 1010 |

|||

|

Serial number |

Drawing number |

Names and specifications |

Quantity |

Material |

Single piece |

Total parts |

Note |

|

Weight |

|||||||

|

34 |

GB/T276-1994 |

Bearing 6301-2Z |

2 |

||||

|

33 |

WY-501W-024-4-04 |

rotor |

1 |

||||

|

32 |

GT/T9125.1-2020 |

Hex Flange Lock Nuts |

2 |

||||

|

31 |

WY-501W-024-04-02 |

stator |

1 |

||||

|

30 |

GB/T857-87 |

light spring washer |

4 |

5 |

|||

|

29 |

GB/T845-85 |

Cross recessed pan head screws |

2 |

Carbon structural steel ML40 for cold upset forging |

M5*120 |

||

|

28 |

GB/T70.1-2000 |

hex head bolt |

2 |

Carbon structural steel ML40 for cold upset forging |

M5*152 |

||

|

27 |

WY-501W-024-4-03 |

lead protective circle |

1 |

||||

|

26 |

WY-501W-J024-04-05 |

Right box |

1 |

Die-cast aluminum alloy YL104 |

|||

|

25 |

GB/T845-85 |

Hex socket head cap screw |

2 |

M5*20 |

|||

|

24 |

GB/T845-85 |

Hexagon Socket Flat Point Set Screws |

2 |

M8*8 |

|||

|

23 |

GB/T276-1994 |

Bearing 6005-2Z |

2 |

||||

|

Serial number |

Drawing number |

Names and specifications |

Quantity |

Material |

Single piece |

Total parts |

Note |

|

Weight |

|||||||

At the heart of the oil-free air compressor is a superior two-stage compressor. The rotor has undergone 20 processes of finishing, so that the rotor line can achieve unparalleled precision and durability. High-quality bearings and precision gears are installed inside to ensure the coaxiality of the rotor and make the rotor fit accurately, so as to maintain long-term efficient and reliable operation.

Oversized anti-friction bearings easily carry all loads to keep the machine running properly. In the critical sealing link, the anti-air leakage seal is made of stainless steel, while the anti-oil leakage seal adopts a durable labyrinth design. This set of seals can not only prevent impurities in the lubricating oil from entering the rotor, but also prevent air leakage and ensure a continuous flow of clean, oil-free compressed air.

In order to optimize the speed and rotor life, another advantage of the oil-free screw compressor is that the main engine uses precision gears, and an improved lip seal is installed at the input end of the drive gear shaft to prevent oil leakage into the unit.

Precautions for use

1. When the oil-free compressor is shut down due to a power failure, in order to prevent the compressor from starting under pressure, the pressure switch power-off handle should be pulled when starting up again, and the air in the pipeline should be drained, and then the compressor should be restarted.

2. The user must set the compressor protection grounding wire to ensure that all metal casings of the oil-free compressor are in good contact with the earth, and the grounding resistance should meet the national standard.

3. When the oil-free compressor finds serious air leakage, abnormal noise, and peculiar smell, it must stop running immediately, and it can only run again after finding out the cause and eliminating the fault and returning to normal.

4. The air compressor is an oil-free air compressor, and the friction parts are self-lubricating, so do not add lubricating oil.

5. The air compressor must be fixed on a ventilated, stable and solid working surface. In order to reduce noise and vibration, a shock absorber must be installed.

6. The filter medium (foam sponge or felt) in the filter should be cleaned every three months, blow off the dust on the medium, wash it with water if necessary, and dry it before use.

7. The oil-free compressor should be maintained at least once a quarter. The maintenance content includes thoroughly removing the dust and dirt outside the compressor, checking and tightening the connecting bolts around the compressor, whether the grounding wire is intact, and checking whether the electrical circuit is aging or damaged. .