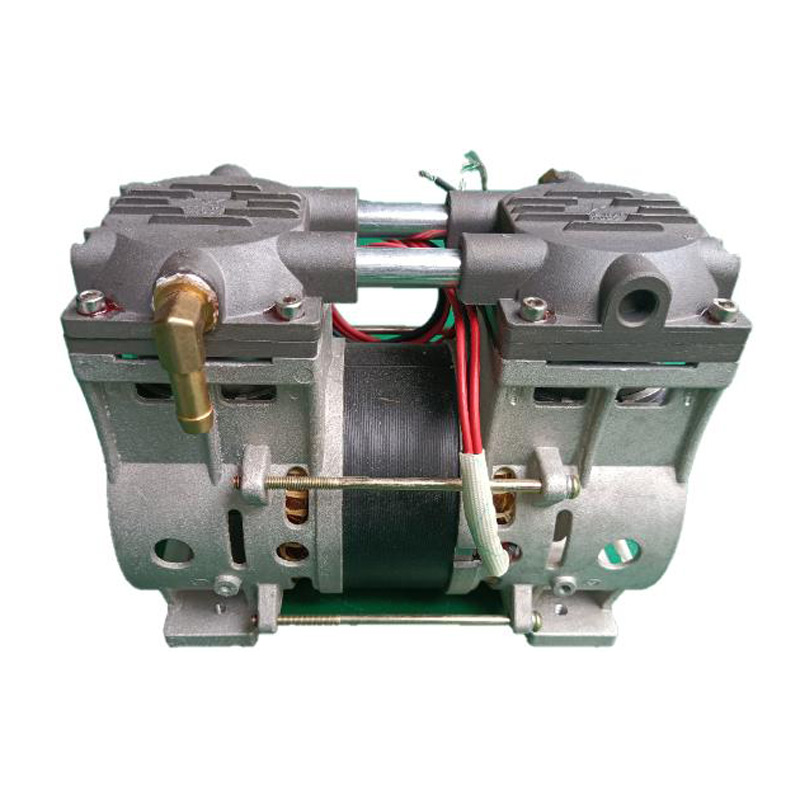

Oil Free Compressor For Oxygen Generator ZW-75/2-A

Product Introduction

| Product Introduction |

| ①. Basic parameters and performance indicators |

| 1. Rated voltage/frequency:AC 220V/50Hz |

| 2. Rated current:1.8A |

| 3. Rated power:380W |

| 4. Motor stage:4P |

| 5. Rated speed:1400RPM |

| 6. Rated flow:75L/min |

| 7. Rated pressure:0.2MPa |

| 8. Noise:<59.5dB(A) |

| 9. Operating ambient temperature:5-40℃ |

| 10. weight:4.6KG |

| ②. Electrical performance |

| 1. Motor temperature protection:135℃ |

| 2. Insulation class:class B |

| 3. Insulation resistance:≥50MΩ |

| 4. Electrical strength:1500v/min(No breakdown and flashover) |

| ③. Accessories |

| 1. Lead length : Power-line length 580±20mm, Capacitance-line length 580+20mm |

| 2. capacitance:450V 8µF |

| 3. Elbow:G1/4 |

| 4. Relief valve: release pressure 250KPa±50KPa |

| ④. Test method |

| 1. Low voltage test :AC 187V. Start the compressor for loading, and do not stop before the pressure rises to 0.2MPa |

| 2. Flow test : Under the rated voltage and 0.2MPa pressure, start to work to a stable state, and the flow reaches 75L/min. |

Product Indicators

|

Model |

Rated voltage and frequency |

Rated power(W) |

Rated current(A) |

Rated working pressure(KPa) |

Rated volume flow(LPM) |

capacitance(μF) |

noise(㏈(A)) |

Low pressure start(V) |

Installation dimension(mm) |

Product dimensions(mm) |

weight(KG) |

|

ZW-75/2-A |

AC 220V/50Hz |

380W |

1.8 |

1.4 |

≥75L/min |

10μF |

≤60 |

187V |

147×83 |

212×138×173 |

4.6 |

Product Appearance Dimensions drawing: (Length: 212mm × Width: 138mm × Height: 173mm)

Oil-free compressor(ZW-75/2-A)for oxygen concentrator

1. Imported bearings and sealing rings for good performance.

2. Less noise, suitable for long-term operation.

3. Applied in many fields.

4. Energy saving and low consumption.

The compressor is the core of the components of the oxygen generator. With the advancement of technology, the compressor in the oxygen generator has also developed from the previous piston type to the current oil-free type. Then let’s understand what this product brings. the benefits of:

The silent oil-free air compressor belongs to the miniature reciprocating piston compressor. When the motor uniaxially drives the crankshaft of the compressor to rotate, through the transmission of the connecting rod, the piston with self-lubrication without adding any lubricant will reciprocate, and the working volume composed of the inner wall of the cylinder, the cylinder head and the top surface of the piston will be generated. Periodic changes. When the piston of the piston compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases. At this time, the gas moves along the intake pipe, pushes the intake valve and enters the cylinder until the working volume reaches the maximum. , the intake valve is closed; when the piston of the piston compressor moves in the reverse direction, the working volume in the cylinder decreases, and the gas pressure increases. When the pressure in the cylinder reaches and is slightly higher than the exhaust pressure, the exhaust valve opens, and the gas is discharged from the cylinder , until the piston moves to the limit position, the exhaust valve is closed. When the piston of the piston compressor moves in reverse again, the above process repeats itself. That is: the crankshaft of the piston compressor rotates once, the piston reciprocates once, and the process of air intake, compression, and exhaust is successively realized in the cylinder, that is, a working cycle is completed. The structural design of single shaft and double cylinder makes the gas flow rate of the compressor twice that of the single cylinder at a certain rated speed, and the vibration and noise control is well controlled.